'O' Scale - First with Accurately Scaled Rail Since 1963

Client Photos and comments / descriptions / questions / stories

|

4

03-27-2017

You are welcome to share photos and narrative of your layout, project, and/or modeling issue. Just enter your text, click on the "Choose File" button to select your photo, and Click on the "Submit" button. Your photo must be in .jpg or .jpeg format. - We reserve the right to remove uploads that are discriminatory or in bad taste.

| |

|

6

03-29-2017

Pure Right O Way!

Just plain nice looking. These turnouts have been in operation for 3+ years without a hitch.

| |

|

7

03-29-2017

Points of a curved #7 turnout. ROW detail is as good as it gets.

| |

|

9

03-29-2017

another photo from Pete

OK, I shrank this from 1.3 meg to 684 K. Lets see.

|

|

|

10

03-29-2017

ROW point detail on curved #7 RH

|

|

|

12

03-29-2017

Thanks Pete! They look great.

Do you build turnouts, crossovers, double slip switches for other modelers?

Jay

| |

|

13

03-29-2017

Hi Jay,

Thanks for asking. I have attached an example of what I like to do. This is a 7 switch module, fully finished and fully operable with manual switch machines, electrical connections, stain, paint and ballast. At $65 each the switches were $455. paint, stain, ballast and extra track were $150. I built the 1x2 platform for another $100. Total: $705. Delivered at the March Meet in Chicago.

If it's OK, I will post a few more examples very soon.

thanks

Pete.

|

|

|

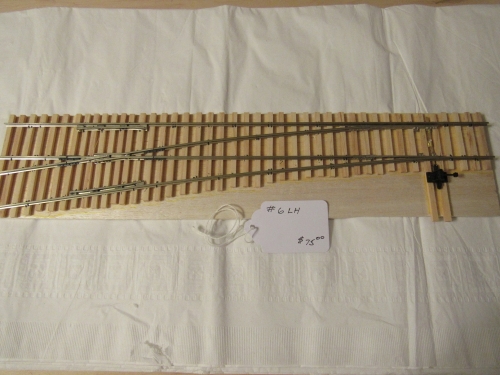

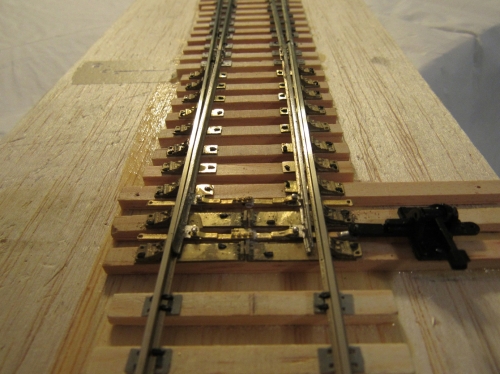

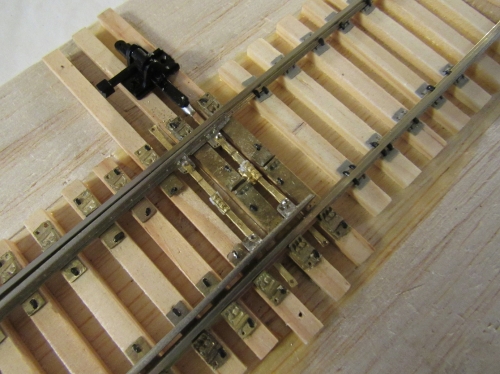

14

03-31-2017

This is a standard fare #6LH turnout. Following I will add photos of the frog and points detail. Base price is $65. Most folks prefer the hand throw machine attached and that is $10 extra. At this moment, 5's, 6's, 7's and 8's all run the same price.

Thanks

Pete.

|

|

|

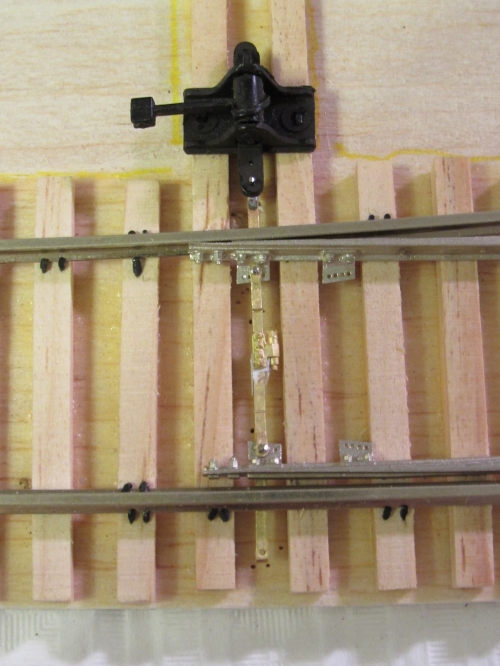

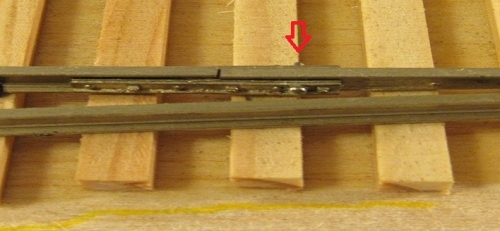

15

03-31-2017

In reference to item 14 (3/31/17) above, this is the frog for the same switch. Perfect gauge guaranteed.

|

|

|

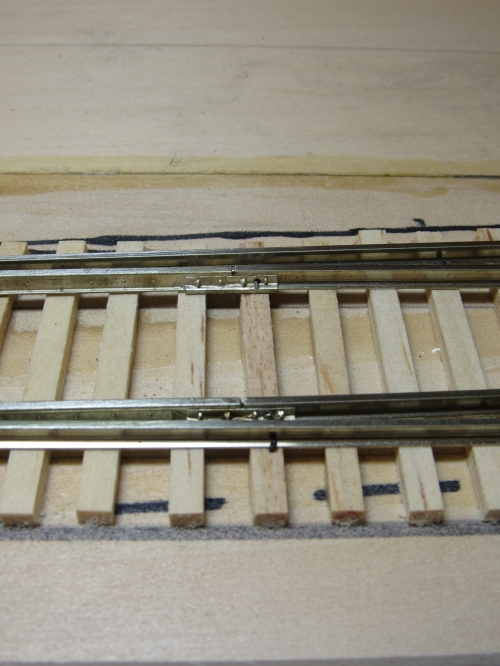

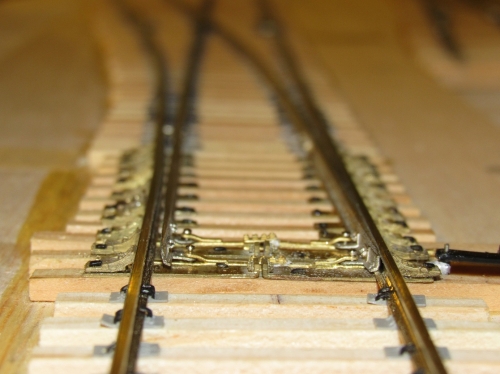

16

03-31-2017

Again, referencing items 14 and 15 these are the points for the #6LH turnout. The movement is excellent and reliable. In our opinion, ROW point and throw bar detail is as good as it gets.

Thanks Pete.

| |

|

17

03-31-2017

OK, lets try this again, only With a photo.

Please see items 14, 15 and 16 above.

Thanks, Pete

Response: Thanks Pete! |

|

|

18

04-06-2017

Nickel silver rail.

Dick

| |

|

20

04-07-2017

I'm attempting to attach a video, created by Chris, that shows how easy it is to bend ME flex track using an, elegant in it's simplicity, tool made from a scrap piece of wood. If the link doesn't work try copy & paste.

Well worth the time spent.

https://www.youtube.com/watch?v=y_R-j8QJJnk&feature=youtu.be

, Jay

Response: Well, the link didn't in fact, work like I wanted but it can be copied and pasted. | |

|

32

04-11-2017

The next three photos are of what the AREA and PRR referred to as a movable point crossing.

Drawings going back as far as 1901 state that any crossing with an angle equal to a #8 (7.125 degree) or larger (smaller degree) must have movable points.

|

|

|

33

04-11-2017

The movable point turns out to be the heart of the slip crossing in either the single or double version. This photo shows the manual switch machine thrown to the left. Next photo will be to the right.

|

|

|

34

04-11-2017

The pivot or lever in the photos was common practice. There are no circumstances under which the points could be thrown in the same direction at the same time.

Hand thrown movable points are thought to be relatively uncommon, and certainly by comparison they were. But, inner city transfer trackage where 2 or 3 companies paralleled each other then crossed, often used this type of arrangement. It's just that photos are hard to find!

|

|

|

35

04-11-2017

A comment about photos 32, 33, and 34 above: The points themselves are ROW part number MP48-8's and of course ROW throw bars. Awfully hard to get this kind of detail anywhere else. Jay also supplied the ties, frogs, guard rails, and rail joiners.

Response: Pete, Thank you for taking the time to post photos of your work. Who doesn't love double slips with movable center points? | |

|

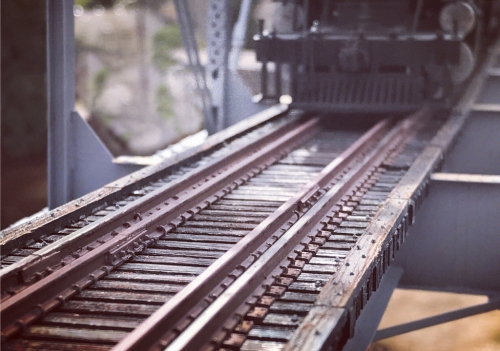

36

04-12-2017

ROW is track! As real as it gets in scale...

| |

|

43

04-12-2017

A test for Erik

|

|

|

44

04-12-2017

Yet another test of a photo provided by Erik.

|

|

|

45

04-12-2017

I just like double slip switches (yeah, I know, I already said that). This was sent to me by Charley Pitts. He is a member of the Bay State Model Railroad Museum. He said, I am a member of the Bay State Model Railroad Museum and worked with Dave Waddington of the O scale RR layout for years. Our RR track uses Right-O-Way components and rail almost exclusively. In fact I think Dave did some master work for Lou. Here are some pictures of a double crossover/slip switch at the north end of the layout. Probably a hundred thousand movements over the switch work. Only one insulated throw bar failed and had to be re-epoxied.

Jay

|

|

|

46

04-12-2017

Second photo from Charley.

Jay

Response: Oops! It's Charlie. Jay |

|

|

48

04-30-2017

Finally laying some track on the new layout! Steal rail going in and Proto48 castings.

Response: Shawn, Looking good! Thank you for sharing. Jay |

|

|

54

06-06-2017

Hi Jay,

Back on March 31 (Item 14) there was an error in my post. The price. Standard price is not $65.00, its $100.00. Very sorry about that. Perhaps the best way to correct is make another posting here and hope everyone sees this.

Want to emphasize: 5's, 6's, 7's and 8's are all the same price. In this case the #7 is $100 while the #6 is $110. The switch machine is $10.

My P:48's are on their way. This is much more fun because you can use real RR drawings - the dimensions don't have to be adjusted.

Pete

|

|

|

55

06-06-2017

This photo and the next show a foolproof way to secure ROW points to the stock rails. An ordinary straight pin turns out to be about a #72. In this photo you will see a #64 hole drilled through the joiners cast on to the points, and the stock rail on the #7 turnout shown above. A little bit of CA (medium thick) on the head will hold the pin but allow the point to swivel.

|

|

|

56

06-06-2017

This is the pin for the #6 above. There is a difference between this and the #7. The 7 uses 16' points which comes with rail joiners cast on. But the 6 uses 10' points cut down from 16'. To do this use the ROW n.s. slip on joiners. CA them to the stock rail. Then use the pin to attach the point.

There is a reason for doing this differently. The cut down point is just ever so slightly wider at the 10' mark.

Using the ROW slip on or cast on joiners with the pins holds the points perfectly in place.

|

|

|

90

07-30-2017

This is a Proto:48 #8 turnout complete with rail braces, appropriately bent tie plates, 14" tie plates, gauge plates, double throw bars, throw rod, etc.

All significant parts from Right-O-Way.

A tiny little 4 wheel diesel switcher goes through smooth as silk.

Thanks for the awesome products Jay.

Pete.

Response: Pete, Thanks for sharing! Would it be possible to show a few more photos? Oh yeah, your welcome. Jay |

|

|

96

08-01-2017

Hi Jay,

This is the #8 frog detail for your Proto:48 code 125 kit. The precision is as close as anything I have ever seen. In a later pic you will see a 4 wheel industrial switcher and box car. They went through these turnouts smooth as glass.

|

|

|

97

08-01-2017

Down at the switch end this is the whole magilla.

Proto:48, code 125, 16' points (#8 frog), gauge plates, rail braces, ties plates, 14" tie plates. As you can guess, electrical contact from stock rails to points is perfect.

And that's an N scale manual switch machine. Holds the points in place nice and tight.

|

|

|

98

08-01-2017

Take a look back at photo/comment 90. The reason for that picture was to show the clevis pins that secure the throw bars to the flanges on the points. I gotta tell you I love this detail!

Here we look down on those same pins. The third (forward) headblock is in case the owner wants to switch from the forward throw bar which was common. The rail braces have to be relieved slightly so the rail base fits in. Once done, the fit is perfect!

|

|

|

99

08-01-2017

And this is the acid test. A Rich Yoder 4 wheel switcher and one of Protocrafts box cars, all Proto:48. I hooked up some alligator clips and ran a line to the frogs. Just smooth as silk. Really cool to watch and operate.

Pete.

|

|

|

315

06-22-2018

A little different use of R-O-W switch points. I model the Western Maryland through Gettysburg PA and they used derails throughout town to protect the mainline. It's a unique detail and adds a extra little operating interest. This is a set of code 125 points that are just for detail purposes on this one. The edge of the layout is a little too close to make it operational but others will be!

Response: Ken, Looks great! Thank you for sharing. Jay |

|

|

1157

05-19-2019

Jay, I recently purchased the parts for a #7 turnout with a self guarded frog from you and today was able to get it roughed in and operational. While I've built a couple dozen or more turnouts to date using ROW parts, this is the first one I've built with a self guarded frog and it is excellent!

Response: Outstanding! Thank you for sharing. |

|

|

1158

05-19-2019

Here is another shot of that #7 turnout.

Response: Looks good John. Sorry to take so long getting these posted. |

|

|

1159

05-19-2019

A RH #10 turnout I've recently installed.

Response: !0s are just cool looking! |

|

|

1160

05-19-2019

Another RH #10 I've recently installed. It's fully operational, just back filling tie plates, spikes, etc.

|

|

|

1161

11-15-2019

Bob Stevenson suggested that you might have a rear truck for the '0' gauge C.P. Huntington model. If so I would appreciate your help purchasing it.

Thank You,

Richard Wright

Response: Richard, Plastic or Brass? Jay |

|

|

1162

04-23-2020

Just getting into Proto48 and I'm having some dumb questions surface. First, I have several brass O scale steamers. Problem as I see it revolves around the O scale wheel gauge being too large for Proto48. That brings up the question of how this can be resolved, if it can be. New drivers or regauging drivers down may not work because there may not be room.

I love the look of Proto48 wheels, are there similar wheels already gauged to O scale track that offer much of the advantage of P48 (fine flanges, etc.) but would work on O scale track? Thanks, probably many have addressed this but I'm still getting into it.

Response: I really need to pay more attention to the comment section. Drivers can be converted to P:48 but it requires skill and experience. The are modelers out here that specialize in doing it. Can you use P:48 wheels gauged to run on regular O Scale track? Yes, it can be done. There are some things you need to be careful; of though. Good track work is critical. | |

|

1163

12-08-2020

Truck dump at Apache Falls on the Apache Falls Branch of the AT&SF.

Consisting of code 138 mainline and code 125 sidings to Proto: 48 standards.

Response: Leonard, It looks good. Can you tell us more about your layout. Thanks for posting the photo. Jay |

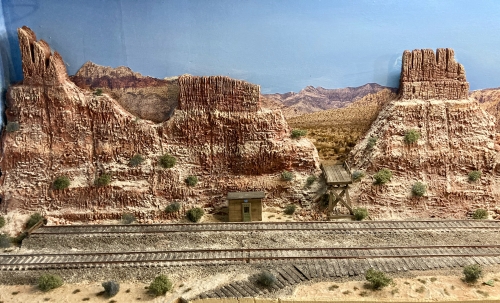

|